A composite material combines two or more distinct materials to create a new material with enhanced properties that surpass its individual components.

Core Components Define Structure

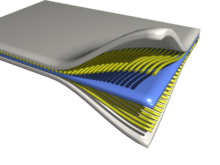

The basic structure consists of a matrix (binder) and reinforcement materials. The matrix surrounds and supports the reinforcement while maintaining their positions. When combined, these materials remain separate and distinct, creating unique mechanical properties.

Historical Evolution Shows Ancient Origins

Humans have used composites since ancient times. The Egyptians created building bricks from straw and mud, while the Ancient Mesopotamians developed plywood around 3400 BC. Wattle and daub, a primitive composite, dates back over 6,000 years.

Modern Applications Transform Industries

Aerospace Leads Innovation

The Boeing 787 and Airbus A350 use composite materials extensively in their wings and fuselage. These materials offer superior strength-to-weight ratios crucial for aircraft performance.

Automotive Industry Embraces Change

Carbon fiber composites now feature in racing car bodies and luxury vehicles. In 2007, the first all-composite military Humvee demonstrated how these materials can reduce weight while maintaining strength.

Types of Composites Shape Usage

Fiber-Reinforced Materials

Fiberglass combines glass fibers with polymer matrices, creating a material that’s strong, stiff, and flexible. Carbon-fiber-reinforced polymers offer even higher performance for aerospace applications.

Particle-Based Composites

These materials use small particles as reinforcement within a matrix. Concrete, the most common composite, uses loose stones (aggregate) held together by cement to create a strong compression-resistant material.

Physical Properties Create Advantages

Composites exhibit anisotropic behavior – their properties change based on force direction. This allows engineers to optimize material orientation for specific applications. The strength-to-weight ratio often exceeds traditional materials, making composites ideal for lightweight, high-performance applications.

Manufacturing Methods Enable Customization

Modern fabrication techniques include automated fiber placement, filament winding, and resin transfer molding. The choice of method depends on the desired properties, production volume, and cost constraints.

Future Developments Drive Innovation

Recent advances include robotic materials that incorporate sensing and computation capabilities. Scientists continue to develop new combinations of materials to meet emerging challenges in aerospace, construction, and sustainable technology.

Citations:

https://en.wikipedia.org/wiki/Composite_material

It has been suggested that this article be split into articles titled Autoclave moulding, Resin transfer moulding, Pressure bag moulding and Light resin transfer moulding. (discuss) (November 2020) |

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Composite materials with more than one distinct layer are called composite laminates.

Typical engineered composite materials include:

- Reinforced concrete and masonry

- Composite wood such as plywood

- Reinforced plastics, such as fiberglass and fibre-reinforced polymer

- Ceramic matrix composites (composite ceramic and metal matrices)

- Metal matrix composites

- and other advanced composite materials

There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with common materials, as well as composite materials inspired from animals and natural sources with low carbon footprint.

More recently researchers have also begun to actively include sensing, actuation, computation, and communication into composites, which are known as robotic materials.

Composite materials are generally used for buildings, bridges, and structures such as boat hulls, swimming pool panels, racing car bodies, shower stalls, bathtubs, storage tanks, imitation granite, and cultured marble sinks and countertops. They are also being increasingly used in general automotive applications. The most advanced examples perform routinely on spacecraft and aircraft in demanding environments.

English

Noun

composite material (plural composite materials)

- Any engineered material composed