Thermoplastics are plastic polymers that become pliable when heated and solidify when cooled. This remarkable property allows them to be reshaped multiple times, making them highly versatile for various applications.

How Thermoplastics Work

Thermoplastics consist of long polymer chains held together by weak intermolecular forces. When heated, these forces weaken, allowing the material to flow. Upon cooling, the forces strengthen again, and the plastic retains its new shape.

Key Characteristics

- Moldability: Thermoplastics can be easily shaped using techniques like injection molding and extrusion.

- Recyclability: Unlike thermosets, thermoplastics can be melted and reshaped multiple times.

- Versatility: They’re used in countless products, from packaging to automotive parts.

Common Types of Thermoplastics

Polyethylene (PE)

Polyethylene is the most common plastic in the world. It’s used in everything from grocery bags to water pipes. There are several types:

- High-density polyethylene (HDPE): Used for milk jugs and outdoor furniture.

- Low-density polyethylene (LDPE): Found in squeeze bottles and plastic bags.

Polypropylene (PP)

Polypropylene is tough and flexible. It’s used in reusable food containers, car parts, and rope.

Polyvinyl Chloride (PVC)

PVC is durable and resistant to chemicals. It’s commonly used in construction for pipes and siding.

Polystyrene (PS)

Polystyrene comes in both rigid and foam forms. It’s used in disposable cutlery and packaging materials.

Advanced Thermoplastics

Some thermoplastics have specialized properties for high-performance applications:

- Polyether ether ketone (PEEK): Used in aerospace and medical implants due to its strength and heat resistance.

- Polycarbonate (PC): Known for its impact resistance and optical clarity, it’s used in eyewear and bulletproof glass.

Environmental Considerations

While thermoplastics’ recyclability is a significant advantage, their widespread use has led to environmental concerns. Proper recycling and waste management are crucial to mitigate their impact.

Future Developments

Researchers are working on bio-based thermoplastics and improved recycling techniques to make these materials more sustainable.

Thermoplastics have revolutionized manufacturing and continue to play a crucial role in our daily lives. Their unique properties make them indispensable in countless applications, from simple household items to advanced technological components.

Citations:

This article needs additional citations for verification. (March 2021) |

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

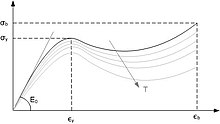

Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped, and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling.

Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully crystallize below the glass transition temperature, retaining some or all of their amorphous characteristics. Amorphous and semi-amorphous plastics are used when high optical clarity is necessary, as light is scattered strongly by crystallites larger than its wavelength. Amorphous and semi-amorphous plastics are less resistant to chemical attack and environmental stress cracking because they lack a crystalline structure.

Brittleness can be decreased with the addition of plasticizers, which increases the mobility of amorphous chain segments to effectively lower the glass transition temperature. Modification of the polymer through copolymerization or through the addition of non-reactive side chains to monomers before polymerization can also lower it. Before these techniques were employed, plastic automobile parts would often crack when exposed to cold temperatures. These are linear or slightly branched long chain molecules capable of repeatedly softening on heating and hardening on cooling.