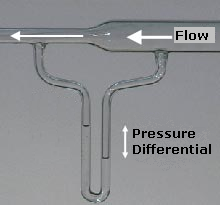

The Venturi effect describes fluid pressure reduction through constricted flow. Named after Italian physicist Giovanni Battista Venturi, this phenomenon balances kinetic energy gains with static pressure losses, enabling applications from flow measurement to carburetion1.

The Venturi Effect Demonstrates Fluid Dynamics Through Constriction

Bernoulli’s principle governs pressure-velocity tradeoffs in Venturi systems. In steady, incompressible flows, narrowing pipe sections accelerate fluids while reducing static pressure. The pressure differential equation p1−p2=ρ2(v22−v12)p_1 – p_2 = \frac{\rho}{2}(v_2^2 – v_1^2)p1−p2=2ρ(v22−v12) quantifies this relationship, where ρ\rhoρ represents fluid density and vvv denotes velocities at wider/narrower sections1.

Choked Flow Limits Venturi Performance

Compressible fluids reach velocity ceilings at sonic speeds. When flow approaches Mach 1 in constrictions, downstream pressure changes cease affecting velocity. De Laval nozzles exploit this limit by combining convergent and divergent sections for supersonic acceleration in rocket engines1.

Venturi Tubes and Orifice Plates Measure Flow Rates

Engineers use constriction-based devices for precise flow quantification. Venturi tubes employ gradual 30° entry and 5° exit cones to minimize turbulence, making them ideal for viscous liquids. Orifice plates offer cheaper alternatives but cause greater permanent pressure loss1.

Flow Equations Connect Geometry to Performance

Volumetric flow rate QQQ depends on cross-sectional areas and pressure drops. The formula Q=A12ρ⋅p1−p2(A1/A2)2−1Q = A_1 \sqrt{\frac{2}{\rho} \cdot \frac{p_1-p_2}{(A_1/A_2)^2 – 1}}Q=A1ρ2⋅(A1/A2)2−1p1−p2 enables calculations without direct velocity measurements. Clemens Herschel adapted these principles in 1888 for large-scale water flow monitoring in Holyoke Canal System1.

Temperature and Pressure Compensation Ensure Accuracy

Real-world applications require environmental adjustments. The ideal gas law modifies flow equations through ΔP=kMPRTn˙2\Delta P = k \frac{MP}{RT} \dot{n}^2ΔP=kRTMPn˙2, accounting for temperature (TTT), molar mass (MMM), and pressure (PPP) variations. Modern instrumentation automatically applies these compensations1.

Differential Pressure Gauges Enable Industrial Applications

Venturi-based sensors monitor critical systems. Jet engines use pressure differentials across constrictions to measure fuel flow rates. Wastewater plants employ similar principles for chemical dosing control through aspirators1.

Venturi Systems Power Diverse Technologies

Carburetors mix fuel using pressure differentials. Airflow through throat constrictions creates low-pressure zones that draw gasoline from float bowls. Bunsen burners and paint sprayers use identical principles for air-gas mixing1.

Architectural Designs Harness Natural Venturi Effects

Building layouts manipulate airflow patterns. Jaipur’s Hawa Mahal channels cool breezes through lattice walls using pressure gradients. New York’s original World Trade Center created ground-level wind tunnels through its narrow tower spacing1.

Historical Innovations Expanded Venturi Applications

19th-century engineers transformed fluid dynamics. While Venturi published initial findings in 1797, Herschel’s 1880s meter designs enabled practical flow measurement. Modern adaptations include protein skimmers in aquariums and bilge pumps in marine engineering1.

Nature Exhibits Venturi-Like Phenomena

Geological formations accelerate atmospheric flows. France’s Rhône Valley intensifies mistral winds through topographic constriction. Mountain passes similarly distort altimeter readings via localized pressure drops1.

Related Principles Enhance Venturi Understanding

The Joule-Thomson effect complements Venturi thermodynamics. Both phenomena involve temperature changes during fluid expansion/compression. Venturi flumes apply these concepts to open-channel flow measurement in irrigation systems1.

zglos

This article's lead section may be too short to adequately summarize the key points. (February 2024) |

The Venturi effect is the reduction in fluid pressure that results when a moving fluid speeds up as it is funneled from one section of a pipe to another, smaller section. As the fluid flows into a smaller area, the fluid's velocity increases, while the static pressure decreases.

The Venturi effect is named after its discoverer, the Italian Physicist Giovanni Battista Venturi, and was first published in 1797.

The effect has various applications in Engineering, Architecture, and everyday objects such as Atomizers that disperse perfume or spray paint and Wine aerators. The reduction in pressure inside the constriction can be used both for measuring the fluid flow and for moving other fluids (e.g. in a vacuum ejector).

English

Etymology

Named after its inventor, the Italian physicist Giovanni Battista Venturi.

Noun

venturi effect (plural

...